Calibrating a vernier caliper is an essential task to ensure accurate measurements in various industries and applications. By calibrating your caliper regularly, you can trust the precision of your measurements and avoid costly errors. In this article, we will guide you through the process of calibrating a vernier caliper step by step, highlighting best practices and addressing common concerns. So, let’s dive in and learn how to calibrate a vernier caliper effectively.

Introduction

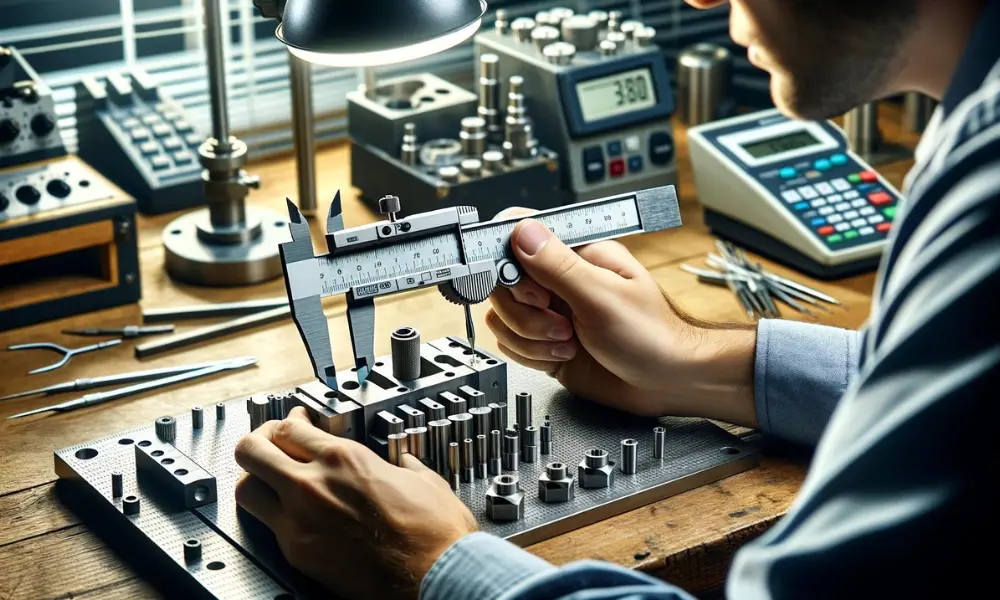

A vernier caliper is a precision measuring instrument used to measure linear dimensions with high accuracy. It consists of a main scale and a sliding vernier scale that allows for precise measurements down to a fraction of the smallest main scale division. Calibrating a vernier caliper involves verifying its accuracy, zero position, and ensuring consistent and reliable measurements.

Understanding Vernier calipers

Before we delve into the calibration process, let’s familiarize ourselves with the vernier caliper itself. A vernier caliper typically comprises three main components: the main scale, vernier scale, and measuring jaws. The main scale provides the primary measurement reading, while the vernier scale improves the accuracy by providing fractional readings. There are different types of vernier calipers available, including standard vernier calipers, digital vernier calipers, and dial vernier calipers, each with its own advantages and applications.

Why Calibrate a Vernier caliper?

Calibrating a vernier caliper is crucial for maintaining measurement accuracy. Even high-quality calipers can experience slight inaccuracies over time due to wear and tear or environmental factors. By calibrating your caliper, you can identify any deviations from the true measurement and make necessary adjustments or corrections. Failure to calibrate a vernier caliper can lead to erroneous measurements, which can have serious consequences in industries such as manufacturing, engineering, or research.

Preparing for Calibration

Before starting the calibration process, you need to gather the necessary tools and ensure a stable environment. The tools may include calibration blocks, gauge blocks, or a certified reference standard. It’s important to perform the calibration in a controlled environment with minimal temperature variations, as temperature can affect the measurements. Additionally, ensure that the caliper is clean and free from debris or contaminants that may interfere with the accuracy of the measurements.

Step-by-Step Guide to Calibrating a Vernier caliper

- Setting the zero position: Start by closing the measuring jaws completely and aligning the zero on the main scale with the zero on the vernier scale. This establishes the zero position and ensures accurate measurements.

- Verifying the accuracy of the zero reading: Check the alignment of the zero mark on the main scale and vernier scale. If they are not perfectly aligned, there may be an error in the zero position. Adjust the zero position if necessary by consulting the caliper’s user manual.

- Checking the accuracy of the measurement scale: Open the jaws and measure a known reference standard, such as a calibration block or a gauge block, with a well-defined dimension. Compare the measurement on the caliper to the known value. If there is a deviation, note the difference and proceed to the next steps.

- Calibrating the depth gauge (if applicable): If your caliper has a depth gauge, verify its accuracy by measuring a known depth standard, such as a gauge block. Compare the measured depth with the known value and make any necessary adjustments.

- Testing the accuracy of the jaws and outside measurements: Measure the outside dimensions of various objects with known dimensions, such as calibration blocks or gauge blocks. Compare the measured values with the known values and note any discrepancies.

- Ensuring accuracy in inside measurements: Measure the inside dimensions of objects with known inner diameters using the caliper’s inside jaws. Compare the measured values to the known dimensions, and if necessary, make adjustments.

Best Practices for Calibrating a Vernier caliper

To achieve accurate and reliable calibration results, consider the following best practices:

- Take multiple readings and average the results to minimize errors caused by external factors or variations in technique.

- Avoid parallax errors by aligning your eyes with the scale and reading it from a perpendicular angle.

- Handle the caliper with care to prevent damage to the measuring jaws or the scales.

- Store the caliper in a protective case or clean environment to minimize the risk of contamination or physical damage.

Troubleshooting and Maintenance

While calibrating your vernier caliper, you may encounter some common issues. Here are a few troubleshooting tips:

- Issue: Zero reading not consistent.

- Solution: Check for any debris or contaminants affecting the zero position and clean the caliper accordingly. If the problem persists, consult the manufacturer or a qualified professional.

- Issue: Jaws not closing uniformly.

- Solution: Inspect the jaws for any obstructions or damage. Clean them thoroughly and check for proper alignment. If the problem persists, consider professional maintenance or replacement.

Regular maintenance is essential to keep your vernier caliper in optimal condition. Here are some tips:

- Clean the caliper after each use to remove any dirt or debris.

- Lubricate the moving parts of the caliper as recommended by the manufacturer.

- Inspect the caliper regularly for signs of wear or damage, and replace any worn-out parts.

Conclusion

Calibrating a vernier caliper is a crucial step in ensuring accurate measurements. By following the step-by-step guide and adhering to best practices, you can maintain the precision and reliability of your caliper. Remember to calibrate your caliper regularly and perform troubleshooting or maintenance as needed to maximize its lifespan and accuracy.

Frequently Asked Questions (FAQs)

Q 1: Why is it necessary to calibrate a vernier caliper?

Answer: Calibrating a vernier caliper is necessary to ensure accurate and reliable measurements. Over time, a caliper can experience slight inaccuracies due to wear, temperature variations, or other factors. Calibration allows you to identify and correct these deviations, ensuring precise measurements.

Q 2: How often should I calibrate my vernier caliper?

Answer: The frequency of calibration depends on the frequency of use, the working environment, and the required measurement accuracy. In general, it is recommended to calibrate a vernier caliper at least once a year. However, if you use the caliper frequently or in critical applications, more frequent calibrations may be necessary.

Q 3: Can I calibrate a vernier caliper myself, or do I need professional assistance?

Answer: You can calibrate a vernier caliper yourself if you have the necessary tools, knowledge, and expertise. However, professional assistance from a calibration laboratory or experienced technician is recommended for precise and accurate calibration, especially for more complex or sensitive calipers.

Q 4: What tools do I need for calibrating a vernier caliper?

Answer: For calibrating a vernier caliper, you may need calibration blocks, gauge blocks, a certified reference standard, and cleaning materials. Additionally, consult the caliper’s user manual for any specific tools or instructions recommended by the manufacturer.

Q 5: What should I do if my vernier caliper is not zeroing properly?

Answer: If your vernier caliper is not zeroing properly, check for any debris, dirt, or obstructions affecting the zero position. Clean the caliper thoroughly and ensure that there are no physical damages or misalignments. If the issue persists, consult the manufacturer or a professional for further assistance.

Q 6: Can I use a damaged vernier caliper for measurements?

Answer: Using a damaged vernier caliper for measurements is not recommended. Damaged calipers can introduce errors and inaccuracies in measurements, compromising the reliability of your results. It is advisable to repair or replace a damaged caliper before using it for precise measurements.

Q 7: How do I maintain the accuracy of my vernier caliper over time?

Answer: To maintain the accuracy of your vernier caliper, follow these maintenance tips:

- Clean the caliper after each use to remove dirt and debris.

- Lubricate the moving parts regularly as per the manufacturer’s instructions.

- Inspect the caliper for wear, damage, or misalignment, and address any issues promptly.

- Store the caliper in a protective case or clean environment to avoid contamination or physical damage.

Q 8: Are digital calipers more accurate than vernier calipers?

Answer: Digital calipers and vernier calipers can both provide accurate measurements when calibrated correctly. Digital calipers offer the advantage of displaying measurements digitally, reducing the chance of human error in reading the scales. However, with proper technique and calibration, both types of calipers can achieve accurate results.