In the pharmaceutical and healthcare industries, maintaining clean and sterile environments is of paramount importance to ensure product safety and quality. Cleanroom validation, a critical process, helps verify that the cleanliness levels in controlled environments meet the specified standards. To achieve this, organizations rely on standard operating procedures (SOPs) that outline the systematic approach to cleaning validation. This article delves into the SOP for cleaning validation and offers insights into creating effective protocols.

Standard Operating Procedure (SOP) for Cleaning Validation/Cleanroom

Introduction

Cleanroom validation plays a vital role in ensuring the integrity of pharmaceutical products, medical devices, and other sensitive manufacturing processes. A cleanroom is a controlled environment where the concentration of airborne particles, microorganisms, and other contaminants is kept within specific limits. Cleanroom validation, therefore, becomes crucial to verify and maintain the cleanliness of such controlled environments.

Understanding Cleanroom Validation

Cleanroom validation is a comprehensive process that involves a series of tests, procedures, and documentation to demonstrate that a cleanroom meets the defined cleanliness standards. It ensures that the environment is suitable for the intended use and minimizes the risk of contamination. The validation process assesses various factors such as air quality, surface cleanliness, particulate counts, and microbial contamination.

Importance of Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) serve as the foundation for effective cleaning validation in cleanrooms. These documents provide a systematic approach to performing cleaning validations consistently and accurately. SOPs define the scope, objectives, responsibilities, and step-by-step procedures involved in the cleaning validation process. They ensure that the validation is conducted in a standardized manner, minimizing errors and variations.

Key Elements of a Cleaning Validation SOP

A well-structured cleaning validation SOP should include several key elements to ensure a comprehensive and effective validation process:

- Scope and Objective: Clearly define the purpose and boundaries of the SOP.

- Responsibilities: Identify the roles and responsibilities of individuals involved in the validation process.

- Procedure Overview: Provide an overview of the entire cleaning validation procedure.

- Acceptance Criteria: Define the acceptance criteria for the validation process, including particle counts, microbial limits, and surface cleanliness.

- Sampling Locations and Frequency: Specify the locations from which samples should be collected and the frequency of sampling.

- Sampling Methods: Outline the sampling methods to be used, such as swabbing, air sampling, or surface contact plates.

- Analytical Methods: Describe the analytical methods and instruments to be employed for sample analysis.

- Validation Protocol: Detail the step-by-step procedures to be followed during the validation process.

- Data Analysis and Interpretation: Explain how to analyze the validation data and interpret the results.

- Corrective Actions and Documentation: Address the actions to be taken in case of deviations or failures, along with the documentation requirements.

- Training and Qualification: Emphasize the importance of personnel training and qualification to ensure the accuracy and reliability of the validation process.

- Maintenance and Monitoring: Provide guidelines for the ongoing maintenance and monitoring of cleanrooms to sustain the validated state.

- Change Control Procedures: Specify the procedures to be followed when making changes to the cleaning validation process.

- Documentation and Record Keeping: Highlight the importance of comprehensive documentation and record keeping throughout the validation process.

- Review and Update: Stress the need for periodic review and update of the cleaning validation SOP to align with changing regulations and best practices.

Developing a Cleaning Validation Protocol

A cleaning validation protocol is a detailed plan that outlines the steps to be followed during the validation process. It acts as a roadmap, ensuring that all necessary activities are carried out systematically. When developing a cleaning validation protocol, it is essential to consider the following:

- Scope and Objective: Clearly define the scope and objective of the validation study.

- Validation Methodology: Identify the appropriate methodology for cleaning validation, such as visual inspection, chemical testing, or microbial monitoring.

- Sampling Plan: Determine the sampling locations, sample sizes, and sampling frequencies based on risk assessment and regulatory requirements.

- Acceptance Criteria: Establish scientifically justified acceptance criteria for each parameter being tested.

- Sample Collection and Analysis: Specify the procedures for sample collection, handling, storage, and analysis, ensuring compliance with relevant standards and guidelines.

- Validation Report: Define the structure and contents of the validation report, including the presentation of data, results, and conclusions.

- Validation Schedule: Create a timeline that outlines the start and end dates of the validation study, as well as the activities to be performed at each stage.

- Risk Assessment: Conduct a risk assessment to identify potential risks associated with the cleaning process and develop mitigation strategies.

- Validation Team: Formulate a multidisciplinary team comprising experts from various relevant departments to ensure a comprehensive and unbiased validation process.

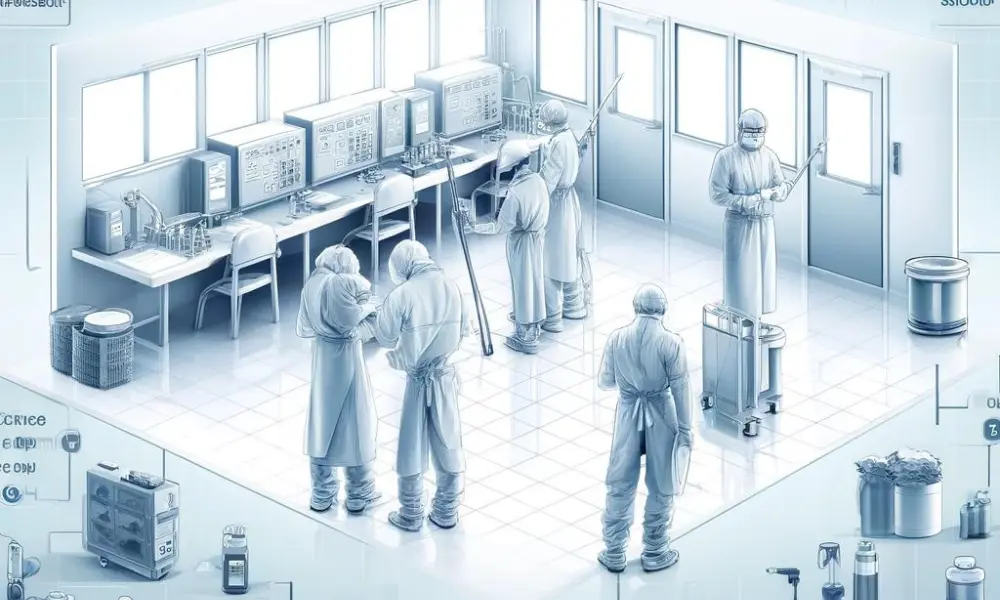

Preparing the Cleanroom for Validation

Before initiating the cleaning validation process, thorough preparation of the cleanroom is crucial. The following steps should be undertaken:

- Cleaning and Disinfection: Clean and disinfect the cleanroom thoroughly using appropriate cleaning agents and validated procedures.

- Equipment Calibration: Ensure that all equipment used in the validation process is calibrated and in good working condition.

- Sampling Plan Execution: Implement the defined sampling plan, ensuring proper sampling techniques and adherence to the predetermined frequencies.

- Documentation Review: Review the documentation related to the cleanroom, including Standard Operating Procedures, maintenance records, and previous validation reports.

- Personnel Training: Provide necessary training to personnel involved in the validation process, ensuring their understanding of the procedures and techniques to be followed.

Executing the Cleaning Validation Procedure

The execution phase of the cleaning validation procedure involves performing the planned activities, collecting samples, conducting tests, and analyzing the results. It includes the following steps:

- Sampling and Analysis: Collect samples from predetermined locations and perform relevant tests, such as particle count measurements, surface swabbing, or air monitoring.

- Testing and Data Collection: Use appropriate analytical methods to analyze the samples and record the results accurately.

- Data Analysis and Interpretation: Analyze the collected data and compare it against the predetermined acceptance criteria.

- Identification of Deviations: Identify any deviations or failures that occur during the validation process, and initiate appropriate corrective actions.

- Documentation: Document all activities, observations, and results meticulously, maintaining a complete and auditable trail of the validation process.

Analyzing and Interpreting the Results

Once the cleaning validation procedure is complete, the collected data must be analyzed and interpreted. This analysis helps determine whether the cleanroom meets the defined acceptance criteria. The interpretation of results involves:

- Data Evaluation: Evaluate the collected data to determine if the defined acceptance criteria are met.

- Trend Analysis: Identify any trends or patterns in the data that may indicate potential issues or deviations.

- Statistical Analysis: Conduct statistical analysis, if applicable, to assess the variability and consistency of the cleaning process.

- Root Cause Analysis: Perform a root cause analysis to identify the underlying reasons for any deviations or failures.

- Conclusion and Recommendations: Draw conclusions based on the data analysis and provide recommendations for corrective actions or process improvements if necessary.

Corrective Actions and Documentation

In cases where deviations or failures are identified during the cleaning validation process, it is crucial to implement appropriate corrective actions. The following steps should be taken:

- Investigation and Root Cause Analysis: Investigate the cause of the deviation or failure and perform a root cause analysis to understand the underlying issues.

- Corrective Actions: Develop and implement corrective actions to address the identified issues, ensuring that they are effective and sustainable.

- Preventive Actions: Implement preventive actions to minimize the likelihood of similar deviations or failures in the future.

- Change Control: Evaluate the need for changes to the cleaning validation process and follow the established change control procedures.

- Documentation: Document all corrective and preventive actions taken, along with the associated investigation and analysis, to maintain a comprehensive record of the validation process.

Training and Qualification of Personnel

To ensure the accuracy and reliability of the cleaning validation process, it is essential to provide adequate training to the personnel involved. The training should cover:

- SOP Familiarization: Ensure that personnel is familiar with the cleaning validation SOP, including its purpose, procedures, and requirements.

- Technical Training: Provide training on specific techniques, equipment, and analytical methods used in the validation process.

- Good Documentation Practices: Emphasize the importance of maintaining accurate and detailed records throughout the validation process.

- Quality Systems Awareness: Educate personnel on relevant quality systems, such as Good Manufacturing Practices (GMP), to foster a culture of compliance and quality.

Maintenance and Monitoring of Cleanrooms

To sustain the validated state of cleanrooms, ongoing maintenance, and monitoring are essential. This includes:

- Routine Cleaning and Disinfection: Establish a regular cleaning and disinfection schedule based on the validated cleaning procedures.

- Equipment Maintenance: Ensure that all equipment used in the cleanroom is maintained, calibrated, and in good working condition.

- Environmental Monitoring: Implement a robust environmental monitoring program to regularly assess the cleanliness of the cleanroom.

- Periodic Reviews: Conduct periodic reviews of the cleaning validation process and associated SOPs to identify areas for improvement and ensure alignment with current regulatory requirements.

Best Practices for Successful Cleanroom Validation

To enhance the effectiveness of the cleaning validation process and ensure successful cleanroom validation, the following best practices should be considered:

- Risk-Based Approach: Apply a risk-based approach when developing the cleaning validation protocol, focusing resources on critical areas and processes.

- Collaboration and Communication: Foster collaboration and open communication among all stakeholders involved in the validation process, including quality assurance, manufacturing, and facilities.

- Continuous Improvement: Embrace a culture of continuous improvement by regularly evaluating and enhancing the cleaning validation procedures and practices.

- Regulatory Compliance: Stay updated with current regulations, guidelines, and industry best practices to ensure compliance during the validation process.

- Validation Lifecycle Management: Adopt a systematic approach to manage the entire lifecycle of the cleaning validation process, from protocol development to periodic review and update.

Challenges in Cleanroom Validation

Cleanroom validation presents several challenges that organizations need to address effectively. Some common challenges include:

- Complexity: Cleanroom validation involves multiple parameters, tests, and analyses, requiring a thorough understanding of the processes and technologies involved.

- Regulatory Compliance: Adhering to evolving regulatory requirements and guidelines can be challenging, necessitating regular updates to validation protocols and procedures.

- Equipment and Instrumentation: Maintaining and calibrating the necessary equipment and instrumentation for cleanroom validation can be demanding, requiring significant investments in resources and expertise.

- Data Integrity: Ensuring data integrity throughout the validation process is crucial, requiring robust documentation practices and adherence to data integrity guidelines.

- Risk Assessment: Conducting accurate and comprehensive risk assessments can be complex, particularly when dealing with multiple variables and potential contamination sources.

Conclusion

Standard Operating Procedures (SOPs) for cleaning validation play a vital role in ensuring the cleanliness and integrity of controlled environments, such as cleanrooms. By following a well-structured SOP, organizations can achieve effective and reliable cleaning validation processes. It is essential to develop comprehensive protocols, execute validation activities meticulously, analyze results diligently, and implement necessary corrective actions. By doing so, organizations can maintain cleanroom compliance, safeguard product quality, and mitigate the risks associated with contamination.

Frequently asked questions for SOP for cleanroom validation

Q1. What is cleanroom validation?

Answer: Cleanroom validation is a process that verifies and maintains the cleanliness of controlled environments, such as cleanrooms, to ensure product safety and quality.

Q2. Why are SOPs important in cleaning validation? SOPs provide a standardized approach to cleaning Answer: validation, ensuring the consistent and accurate execution of the validation process.

Q3. What are the key elements of a cleaning validation SOP? A cleaning validation SOP should include Answer: Elements such as scope and objectives, responsibilities, procedure overview, acceptance criteria, sampling methods, and data analysis procedures.

Q4. How is a cleaning validation protocol developed?

Answer: A cleaning validation protocol is developed by defining the scope and objectives, selecting validation methodology, determining sampling plans, and establishing acceptance criteria.

Q5. What should be considered during the execution phase of cleaning validation?

Answer: During the execution phase, it is important to follow the defined procedures, collect samples, conduct tests, analyze results, and document all activities accurately.

Q6. How are deviations or failures addressed during cleaning validation?

Answer: Deviations or failures are addressed by conducting investigations, performing root cause analysis, implementing corrective actions, and documenting all steps taken.

Q7. Why is training and qualification of personnel important in cleaning validation?

Answer: Proper training and qualification ensure that personnel understand and adhere to the cleaning validation procedures, minimizing errors and ensuring the reliability of the process.

Q8. What are the challenges in cleanroom validation?

Answer: Challenges in cleanroom validation include complexity, regulatory compliance, equipment and instrumentation requirements, data integrity, and accurate risk assessments.